“Cutting ability” and “service life” are two terms that rarely get along in the world of cutting tools. SEMLOC manages the combination!

For the manufacture of blades, there are several criteria that must be taken into account to achieve the best result: Material of the blade, pre-treatment of the same, geometry and grinding, post-treatment or coating, intended use and finally – which price segment can or should I serve with it?

An example to some criteria makes it clearer: One can manufacture blades from metal or from ceramic. And not all steel is the same! If you take as raw material for a blade, for example, a steel grade in which carbon is present in “large” carbide inclusions, you can imagine that no “good” cutting edge can be made from it. Indeed, if such a carbide grain lies exactly on the cutting edge, it will possibly break out already during grinding, and in any case later during use, leaving a nick.

This is an effect that is definitely not needed on a cutter. The SEMLOC BLACKSeries blades are made of “SK2” material (also called “Japan steel SK2”), which is characterized by a high carbon content, but which is incorporated in microcrystalline form in the structure and can therefore never lead to large chipping and nicks.

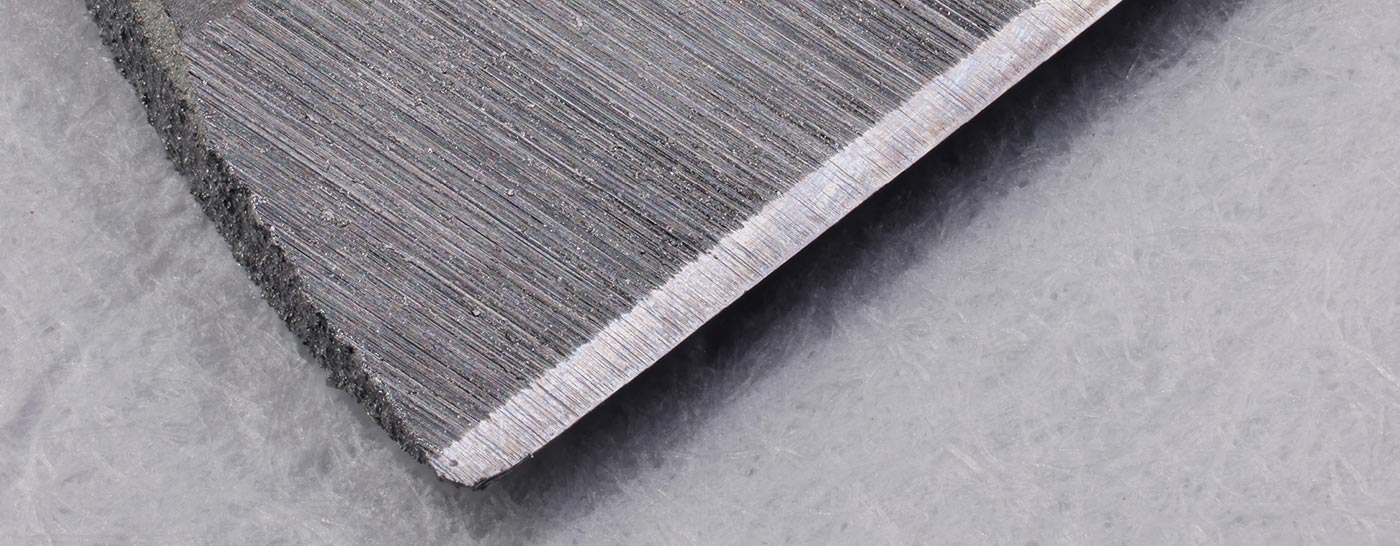

About the geometry: Of course it is easier and also cheaper to grind a blade with only one bevel. This may even be “better” for the initial cutting action, because usually the smallest possible wedge angle is chosen for the cutting edge. However, these blades lose so much of their initial cutting performance already during the first cuts that the user will notice this dulling effect very quickly and will therefore change blades more often.

All SEMLOC blades – not only the BLACKSeries – feature a 3-bevel grind, which corresponds to a doubling (+100%) of the service life compared to blades with only one cutting bevel that are comparable in terms of material, or an increase in service life of 50% compared to equivalent blades with two cutting bevels.

So what does the “SE” or “Sharp Edge Technology” do?

This is a hardening process that uses a laser beam to smooth the unavoidable final grinding burr – which is already very small due to the 3-bevel grind – and fuse it into a cutting edge free of nicks.

This process not only increases the hardness of the cutting edge, but also preserves the initial cut. Last but not least, I would like to discuss the “black color” of the blade.

This is not a marketing gimmick, but the following dual benefit:

Firstly, it provides excellent corrosion protection and

secondly, this layer smoothes the side surfaces of the blade, which would otherwise lead to high friction and an increase in the amount of force required if the cutting edge were to penetrate deeply into the material.

One could highlight many more positive features of BLACKSeries blades.

You will find the most important ones listed below:

What makes SEMLOC BLACKSeries blades so uniquely perfect for the highest demands?

- Multiple lifetime compared to conventional blades

- Highest cutting performance combined with long service life

- Highest possible precision due to burr-free cutting

- Low effort – even for thick or robust materials

- SK2 blade steel + Sharp-Edge laser hardening + blackened sides